Heh, that's also interesting for me to hear. I usually also tend to try and constrain everything and make it as parametric as possible. Since this model became more complex than previous ones I took the liberty to be approximate eg. when lining up the glands and the holes. In the end i just want something printable as quickly as possible. I'll probably never change the dimensions again. It's therefore more time efficient to re model things if I ever need to adjust things.

With the new assembly toolbox I might find an easier way to fit things like the glands and the holes together. Maybe by just tying a cutting object and the gland together and using booleans (which I find quite cumbersome to use).

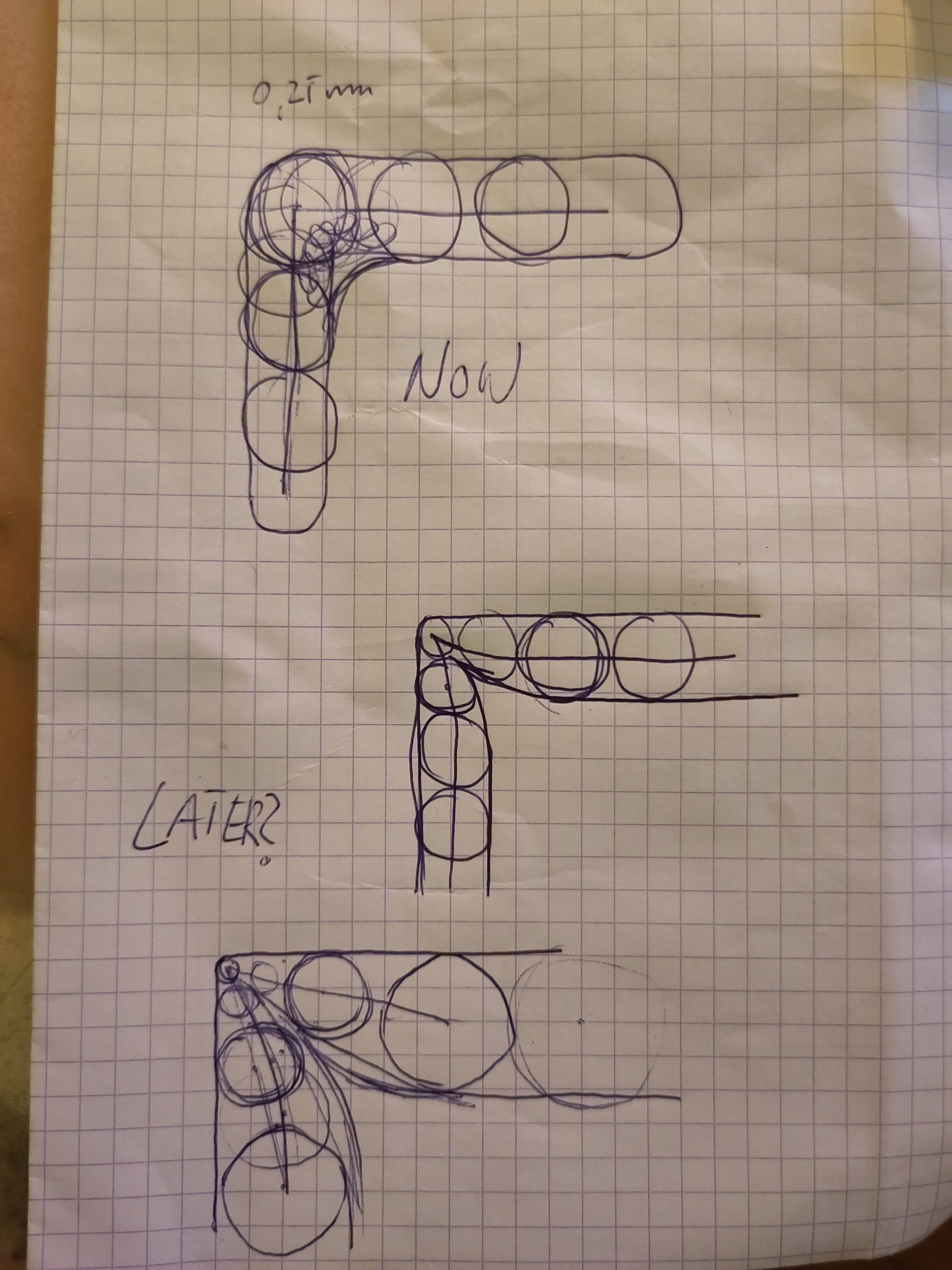

Manual "Exploded view",

Manual "Exploded view", Opaque view.

Opaque view.

Tomatoes are still small but growing nicely.

Tomatoes are still small but growing nicely. The new raspberry bushes produce first red fruits.

The new raspberry bushes produce first red fruits. Bonus: Happy chicken sharing some leftover melon.

Bonus: Happy chicken sharing some leftover melon.

I ran an XMPP network based on prosody and used snikket on android. Can recommend!