3DPrinting

3DPrinting is a place where makers of all skill levels and walks of life can learn about and discuss 3D printing and development of 3D printed parts and devices.

The r/functionalprint community is now located at: !functionalprint@kbin.social or !functionalprint@fedia.io

There are CAD communities available at: !cad@lemmy.world or !freecad@lemmy.ml

Rules

-

No bigotry - including racism, sexism, ableism, homophobia, transphobia, or xenophobia. Code of Conduct.

-

Be respectful, especially when disagreeing. Everyone should feel welcome here.

-

No porn (NSFW prints are acceptable but must be marked NSFW)

-

No Ads / Spamming / Guerrilla Marketing

-

Do not create links to reddit

-

If you see an issue please flag it

-

No guns

-

No injury gore posts

If you need an easy way to host pictures, https://catbox.moe/ may be an option. Be ethical about what you post and donate if you are able or use this a lot. It is just an individual hosting content, not a company. The image embedding syntax for Lemmy is

Moderation policy: Light, mostly invisible

view the rest of the comments

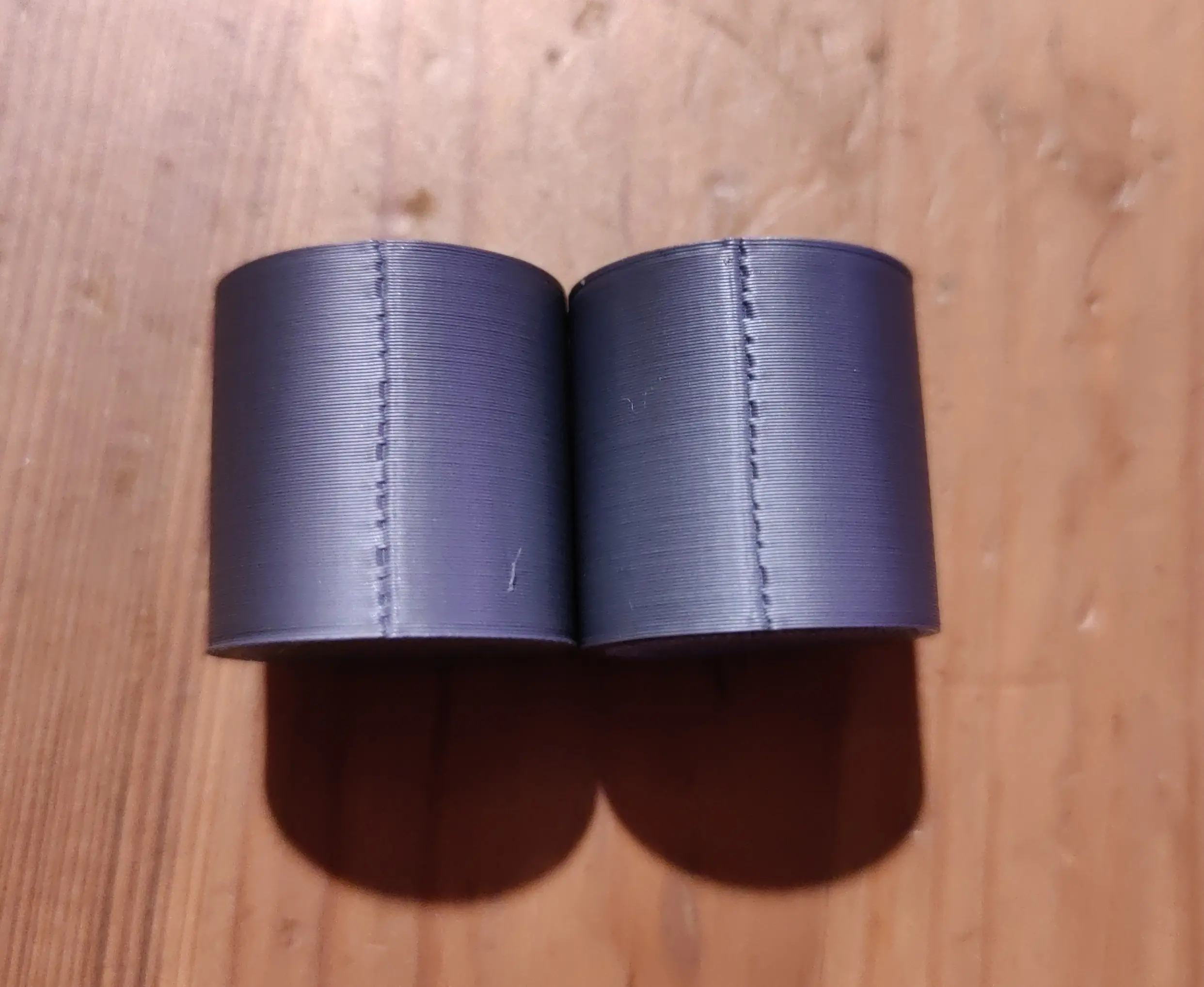

Is the bad side of the seam where it stops or where it starts printing the outer wall? I assume it's where it stops and then it cross the wall to form the infill?

To add to the PA questions, are you sure that your PA setting actually are changing anything?

What printer is this and what firmware?

Does a spiral mode print work fine?

What if you print the part significantly slower (to rule out rigidity/acceleration issues)

Correct, but this still happens when printing without infill, although less.

When printing the PA pattern, I can clearly see a difference. I haven't seen a huge difference in the actual print quality. It doesn't seem to have the any effect on this issue.

It's an anycubic kobra 2 bedslinger running klipper

Tried printing at both 30mm/s and 100mm/s, it looks the same aside from slightly worse ringing at the higher speed.