this post was submitted on 24 Oct 2024

92 points (100.0% liked)

Electronics

2013 readers

10 users here now

Projects, pictures, industry discussions and news about electronic engineering & component-level electronic circuits.

Rules

1: Be nice.

2: Be on-topic (eg: Electronic, not electrical).

3: No commercial stuff, buying, selling or valuations.

4: No circuit design or repair, tools or component questions.

5: No excessively promoting your own sites, social media, videos etc.

Ask questions in https://discuss.tchncs.de/c/askelectronics

founded 1 year ago

MODERATORS

you are viewing a single comment's thread

view the rest of the comments

view the rest of the comments

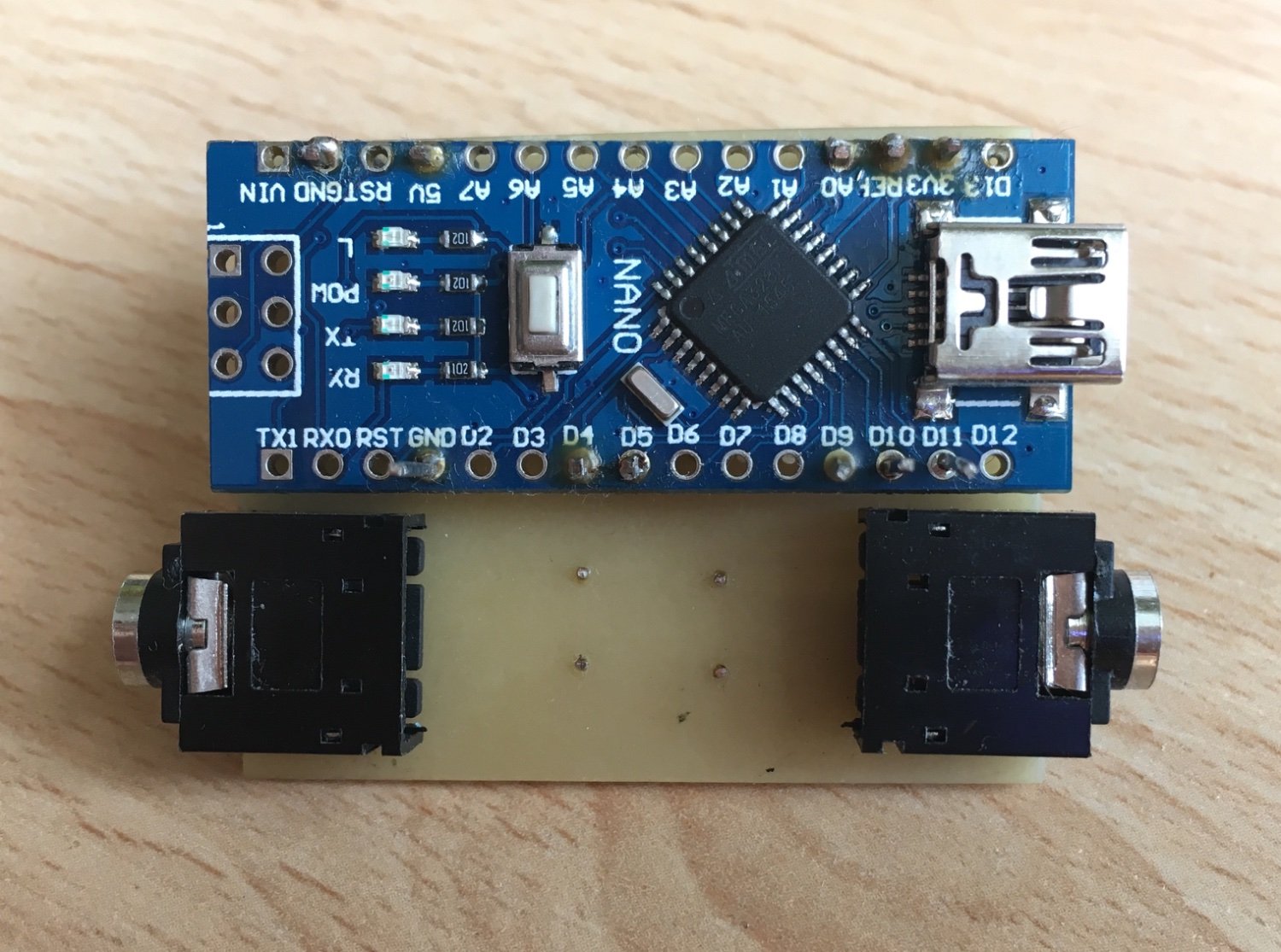

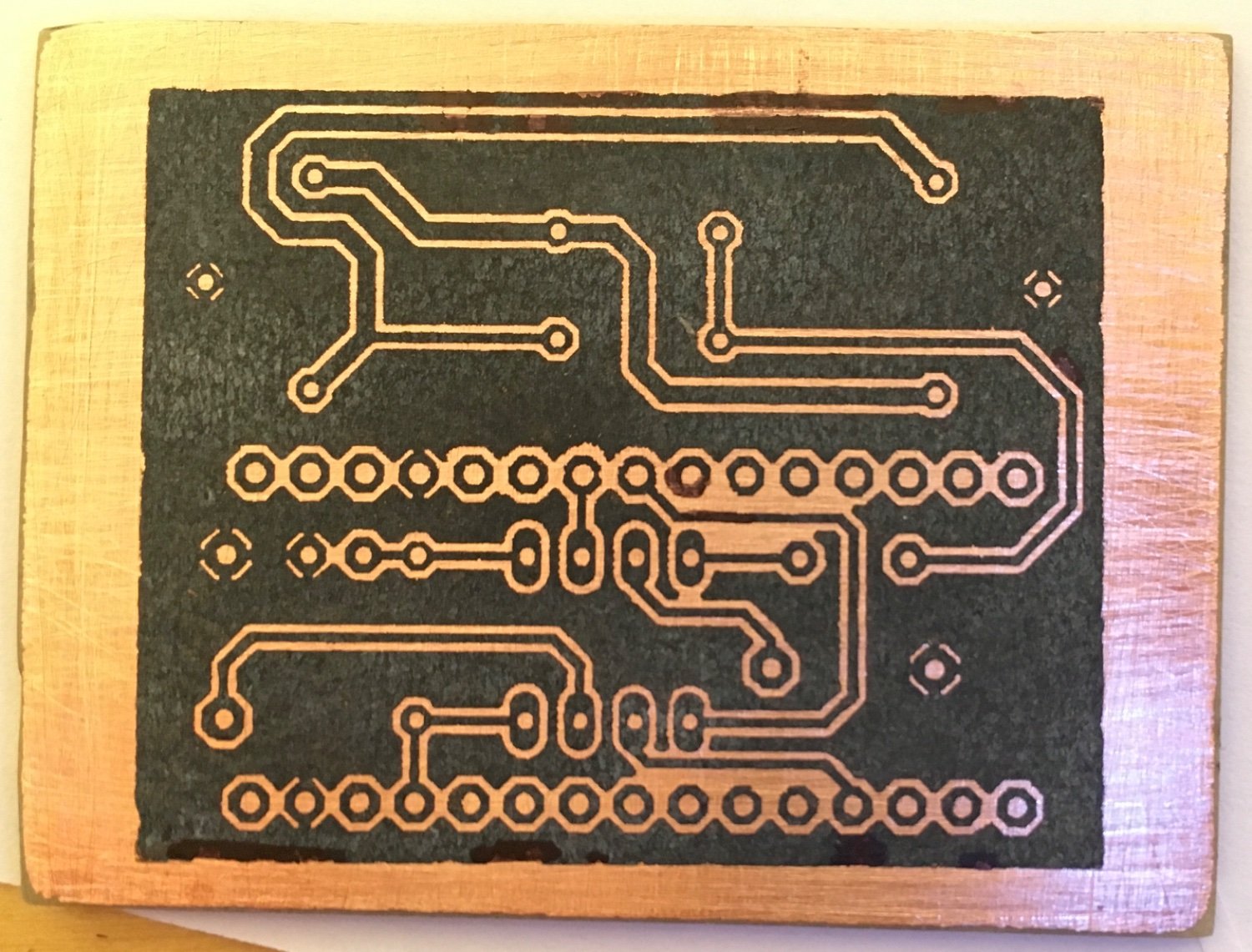

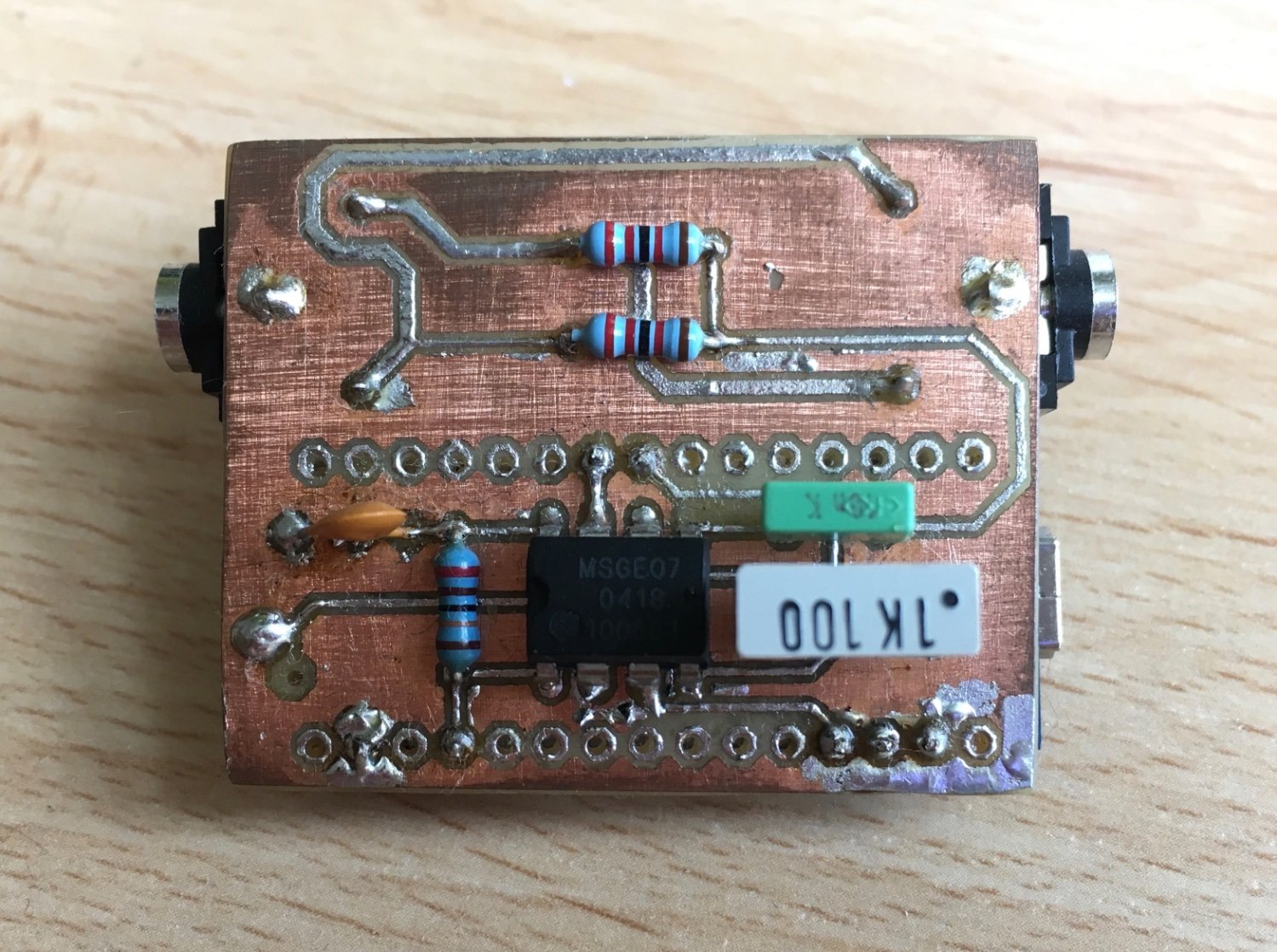

I’m assuming you’re not super familiar with PCB fabrication? The toner transfer is a way to get small, repeatable, and precise definition of the component pads and traces - at home - without needing the expensive industrial machinery that fab houses have.

The toner ’print’ is a negative image, placed on a sheet of copper mounted to (usually) fiberglass. Much like masking off areas when painting, the ‘print’ protects the copper surface in select areas you want to keep safe when the whole board goes into the acid bath to dissolve the unprotected copper - leaving copper only where your ‘print’ was, and hopefully no shorts/grounds.

Definitely cool to have the ability to DIY fine pitch if you’re manually mounting SMT components or want higher board density, beats out the hand drawn permanent marker lines I’ve done in the past 😅