Being transparent, I saw this post in my ALL feed. I love this conversation as it gives me insights to a community I would never have known about. In my house Im the one with a sewing kit, I do all the minor repairs, rips, buttons, etc. I have done some basic crosstich pieces as a child. With all respect, I have never, ever considered that needles could lose functionality. With respect, why not just replace the needles? Why bother electroplating? What am I missing? I truly mean no offense, y'all have just blown my mind with you passion for needles.

Cross stitch and embroidery

Share your stitching and meet new crafty folks! All forms of embroidery and all skill levels welcome 🪡

-

All instance rules apply: see sidebar at sh.itjust.works

-

WIP/FO Posts should include pattern details (at least name, preferably link).

-

Relevant self-promo from community members is acceptable but will be handled on a case-by-case basis. Exclusively salesy posts may be removed.

I'm at the point where I think replacing it is probably what I'll do, although there have been some good suggestions here. For the record, I do have more needles lol! I've been sewing since I was a teenager and have just never seen a needle turn black like this, so for me it was just kind of interesting! I'm guessing it's something specific to cross stitching? I had never spent an hour or two per night sewing until I started this hobby about a month and a half ago, so I'm guessing this just wears out needles faster than stitching my clothes back together does

Good thing I lose my needles too quickly for this to ever happen to me. /s

I’m guessing those are cheaper needles, and nickel plated. Have you tried either jewelry cleaner, or something like “never dull”?

I’d guess if you wash your hand before handling, and clean them (needles) after use, they will last a lot longer. Even wiping down with something like a string cleaner cloth (for guitar) would help

Have you tried polishing? You can usually just take a bit of flitz or similar metal polish and just roll the needle around on a flat surface with your finger and get the surface smooth, even if not all the oxidation gets removed.

But yeah, needles aren't expensive enough to worry about, it would only be for frugality and the RRR factor.

My grandma would just reserve blackened needles for dirty work like patching up my grandfather's coveralls that he would use when working on a car or whatever and tear something enough that it needed repair before washing.

I did try polishing! It did smooth out the needle slightly, but it only lasted about 2 days before the texture got rough again

In machining, some people have 'rusty hands,' or 'acid hands,' and cause bare metal to corrode faster. Doesn't seem to be a consensus on why. Maybe salty sweat, maybe some particular oil in their skin. It could be that your extended stitching stresses your hands & fingers and encourages them to secrete something that shorter sessions don't. The solution in machining is to wear gloves or to coat everything in oil, cosmoline, or boeshield, but those won't work for metal that is constantly abraded, like needle going through canvas.

You might try hitting your needles with some WD-40 or 3-in-1 oil when you finish a session, or keeping them in an oiled case, but then you've probably got to clean them before use.

Might also be able to rub them down with a high-melting wax, like carnuba or machinable wax to fill in the corrosion pits once they get rough, but needles are probably cheap enough just to throw out when they get too rough to slide easily.

You could try replating them with nickel or rhodium at home. Electrolysis is pretty easy to do with minimal costs. You pretty much just need a cheap bench power supply, a Tupperware container, solution, and a piece of the metal you want to put on the needle. All of which you can get easily and cheaply on Amazon.

Probably run you a little more than $100 up front, but it can be done repeatedly before you’d notice the diameter of the needle increasing in any significant way. And of course it could be used to plate other things too. The whole process is pretty neat and it’s handy to be able to do it.

I did consider that, but I really can't afford to spend $100 on a power supply right now.

Another idea would be to lean into them being black and use a bluing agent. $10 or so for a small bottle that will last forever and will help a new needle avoid corrosion for a long time. That’s what they use on guns for the same reason.

Steel is often treated with black oxide finish on tools and objects that are to be handled. Drill bits, guns, lots of stuff. You could probably rub the item with kerosene or mineral oil if it's rubbing on fabric in a way you don't like. Industrial looms use these to lubricate machines so thread flies along where it needs to go, without snags. Might be able to use parafin wax or BLO/beeswax for a longer lasting lubricating finish.

But yeah, as I said before (I think it was in response to your earlier thread) it's just from handling. Won't come off on fabric or anything. It's part of the metal now. Larger metal pieces could be polished on a wire wheel or grinding wheel, but there's not much metal here. Best to just keep using it while you can. Maybe coat it with a very mild clear lubricant/sealer.

well I can get like 10 needles for a few bucks. Not worried...

Considering needles are like $8 for 20 (I’m using Gold plates Permin) is it really that big an issue? I’ve done like 20.000 stitches without it turning black. It’s getting darker but isn’t an issue at all yet.

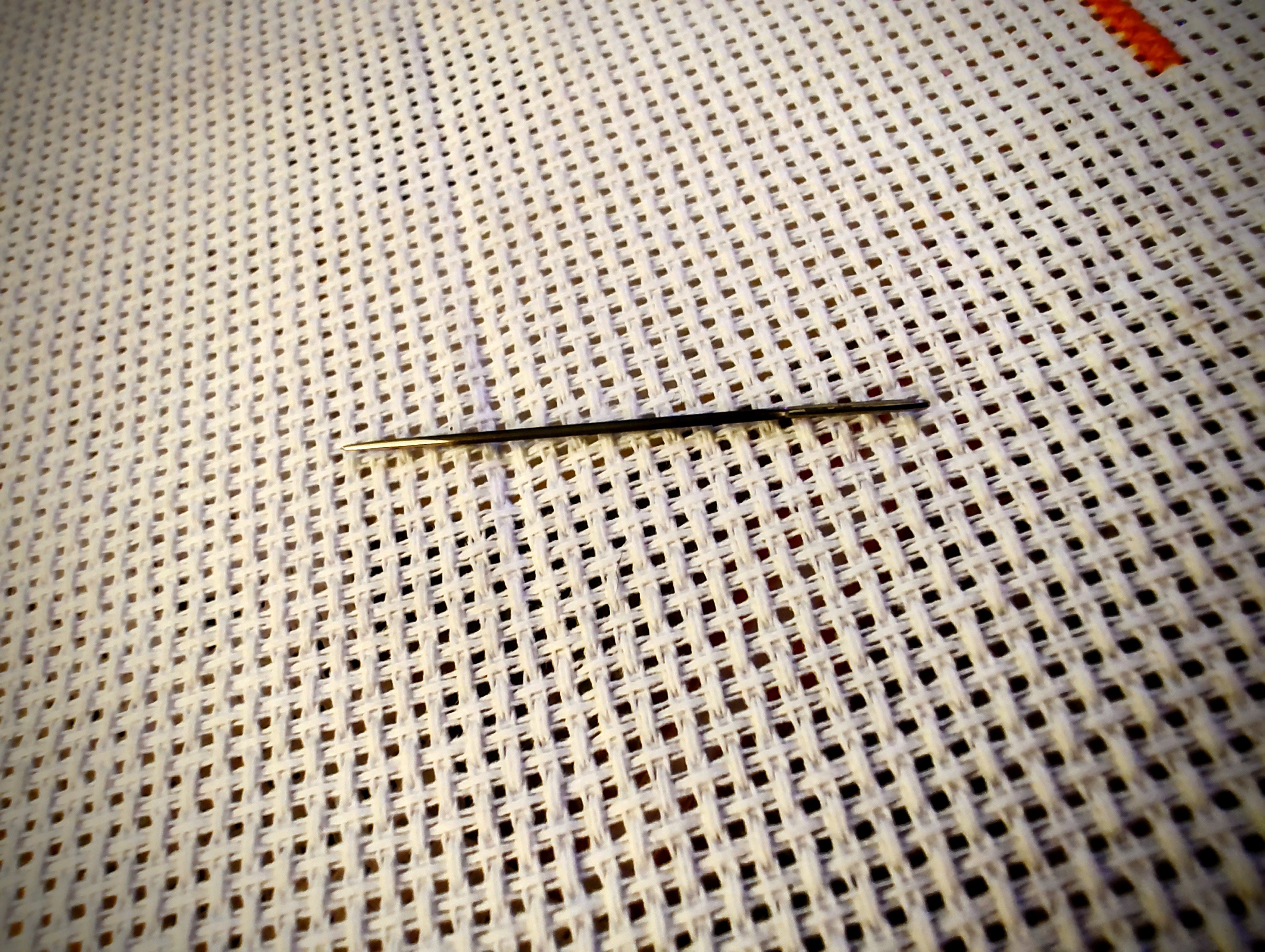

Just curiosity mostly. I hadn't seen a sewing needle turn black like this before.