this post was submitted on 29 Jul 2023

26 points (100.0% liked)

Cross stitch and embroidery

1115 readers

1 users here now

Share your stitching and meet new crafty folks! All forms of embroidery and all skill levels welcome 🪡

-

All instance rules apply: see sidebar at sh.itjust.works

-

WIP/FO Posts should include pattern details (at least name, preferably link).

-

Relevant self-promo from community members is acceptable but will be handled on a case-by-case basis. Exclusively salesy posts may be removed.

founded 1 year ago

MODERATORS

you are viewing a single comment's thread

view the rest of the comments

view the rest of the comments

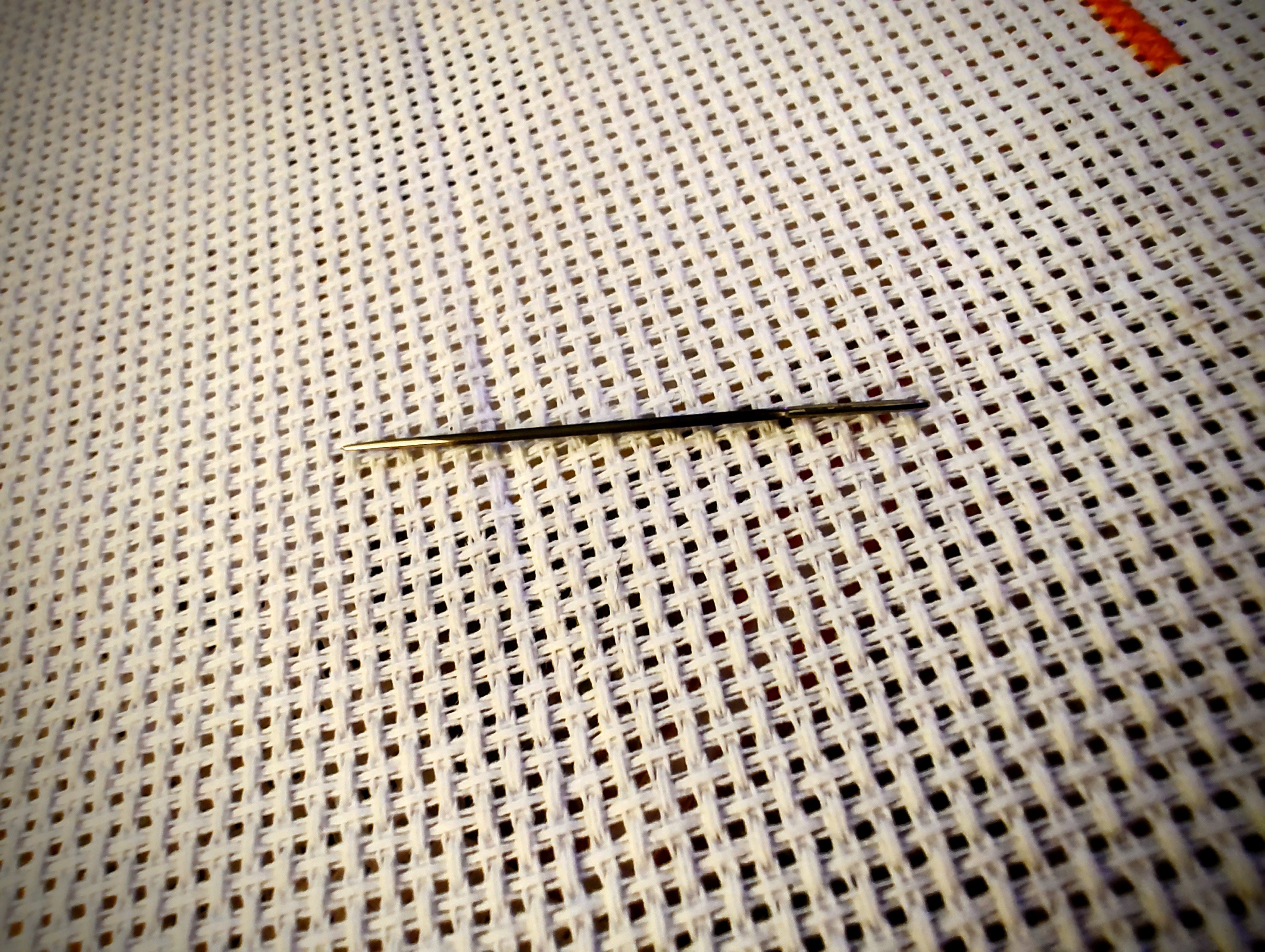

Steel is often treated with black oxide finish on tools and objects that are to be handled. Drill bits, guns, lots of stuff. You could probably rub the item with kerosene or mineral oil if it's rubbing on fabric in a way you don't like. Industrial looms use these to lubricate machines so thread flies along where it needs to go, without snags. Might be able to use parafin wax or BLO/beeswax for a longer lasting lubricating finish.

But yeah, as I said before (I think it was in response to your earlier thread) it's just from handling. Won't come off on fabric or anything. It's part of the metal now. Larger metal pieces could be polished on a wire wheel or grinding wheel, but there's not much metal here. Best to just keep using it while you can. Maybe coat it with a very mild clear lubricant/sealer.