this post was submitted on 29 Jul 2023

26 points (100.0% liked)

Cross stitch and embroidery

1115 readers

1 users here now

Share your stitching and meet new crafty folks! All forms of embroidery and all skill levels welcome 🪡

-

All instance rules apply: see sidebar at sh.itjust.works

-

WIP/FO Posts should include pattern details (at least name, preferably link).

-

Relevant self-promo from community members is acceptable but will be handled on a case-by-case basis. Exclusively salesy posts may be removed.

founded 1 year ago

MODERATORS

you are viewing a single comment's thread

view the rest of the comments

view the rest of the comments

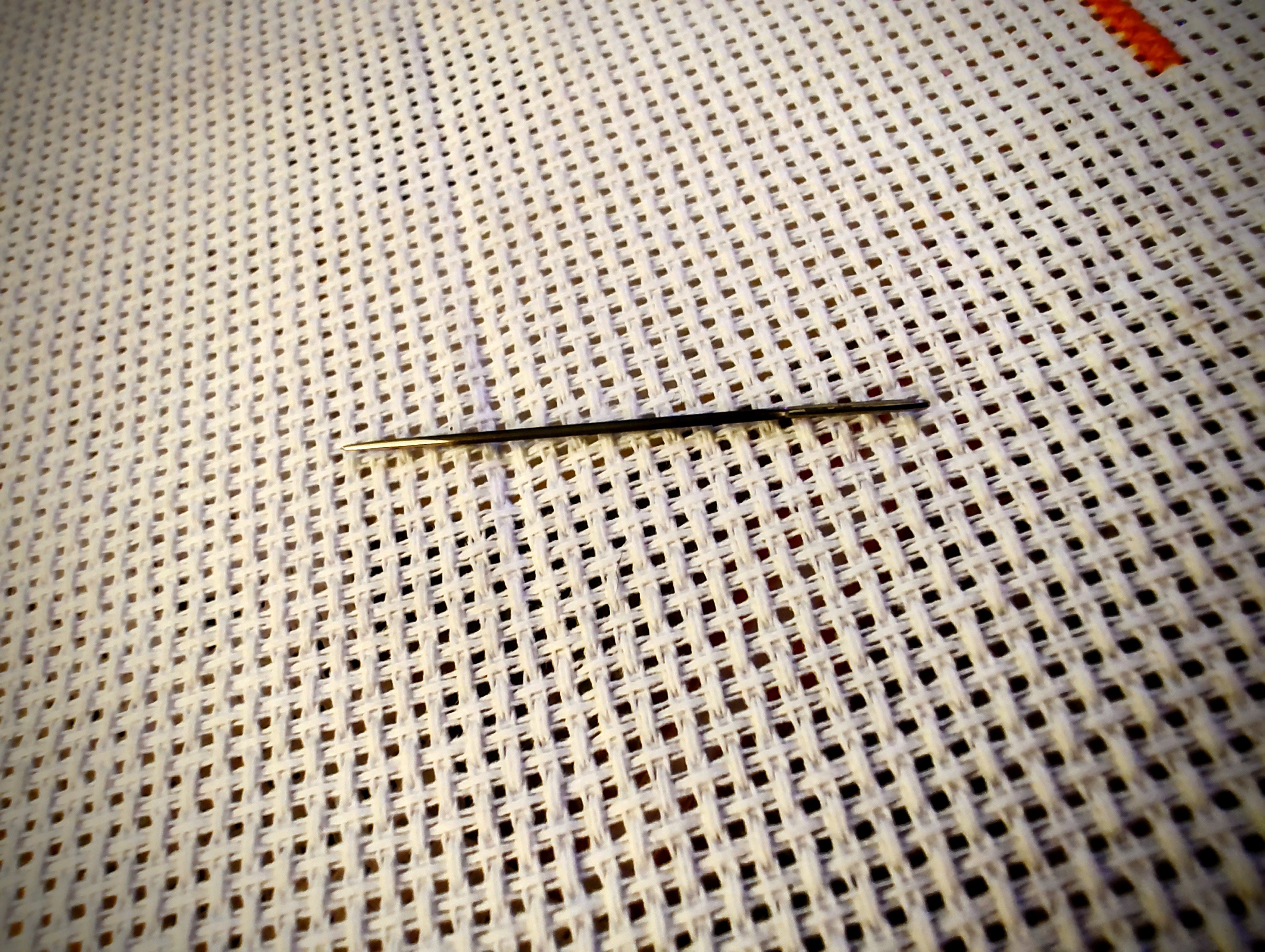

You could try replating them with nickel or rhodium at home. Electrolysis is pretty easy to do with minimal costs. You pretty much just need a cheap bench power supply, a Tupperware container, solution, and a piece of the metal you want to put on the needle. All of which you can get easily and cheaply on Amazon.

Probably run you a little more than $100 up front, but it can be done repeatedly before you’d notice the diameter of the needle increasing in any significant way. And of course it could be used to plate other things too. The whole process is pretty neat and it’s handy to be able to do it.

I did consider that, but I really can't afford to spend $100 on a power supply right now.

Another idea would be to lean into them being black and use a bluing agent. $10 or so for a small bottle that will last forever and will help a new needle avoid corrosion for a long time. That’s what they use on guns for the same reason.